Products

Fly Ash Bricks

A Brief History

More about Fly Ash Bricks

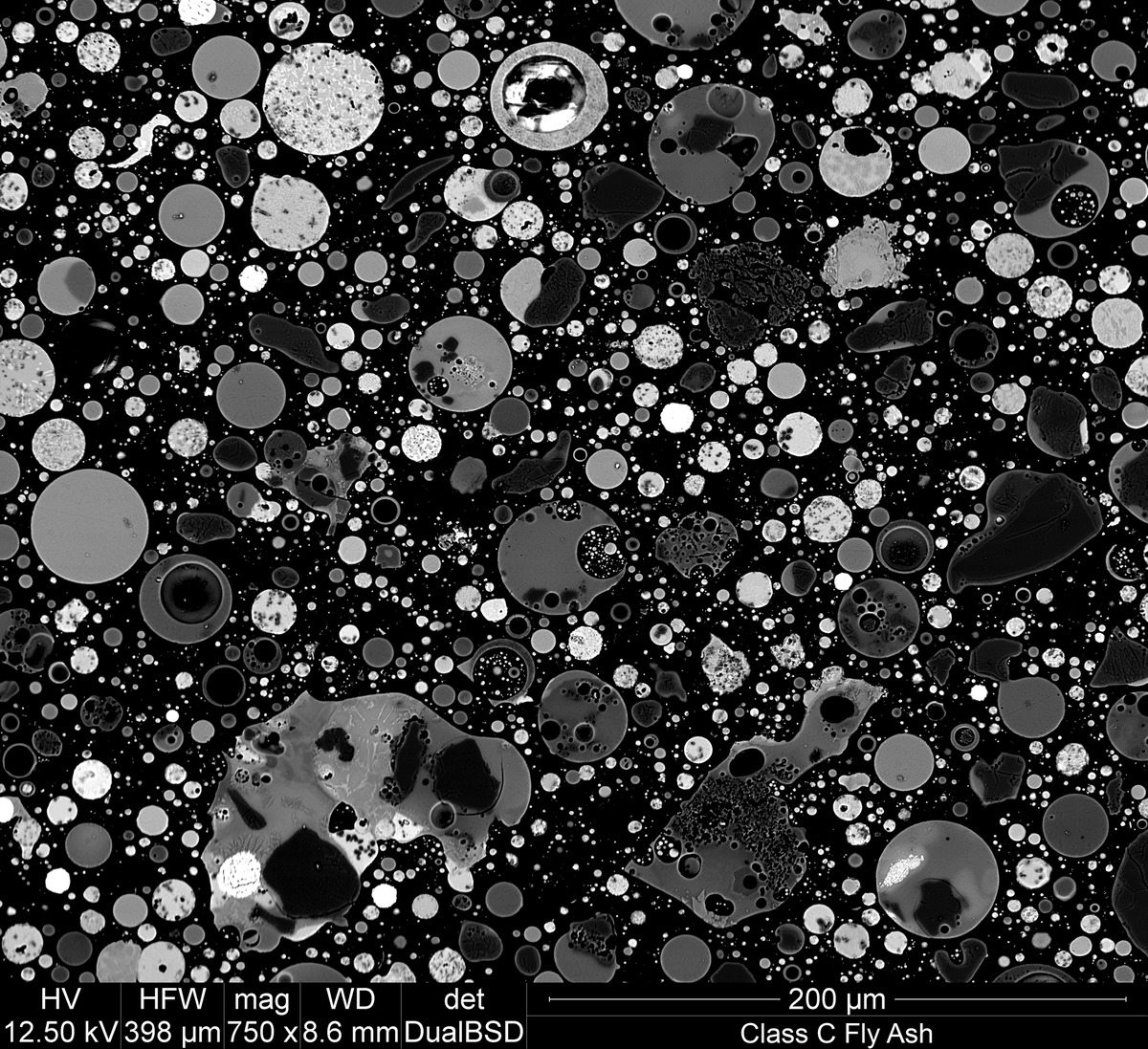

Fly ash bricks are manufactured by mixing Fly Ash, Cement, Slag, Lime, and Gypsum. Usually, fly ash replaces 10% to 20% of the actual cement volume. Cast in a machine mold, they have a more uniform appearance and smooth finish. And also, Fly Ash Bricks Manufacturing is more environmentally friendly.

They are 28% lighter than regular clay bricks but have a greater than 40 MPA compressive strength than standard bricks. As a result, they are inexpensive and eliminate the need for plaster. And Fly Ash Bricks can reduce high construction costs and soil erosion.

Light in weight, Fly Ash Bricks are suitable for multi-story buildings because as the height of the buildings increases, the stress and strain on the foundation and structure decreases comparatively.

These types of bricks are being used worldwide, and especially in India, after the Government of India has reinstated using Fly Ash, instead of Clay Bricks, within a 100-mile radius of coal power plants.

Request Quote!

Fly Ash Bricks

Cost

Fly Ash Bricks are comparatively cheaper, compared to traditional clay bricks.

Mortar

Mortar consumption is reduced drastically by 50%, thus further decreases manpower.

Water Consumption

Water required to manufacture Fly Ash Bricks is 50% less. A Great Solution for water conservation.

Wastage

Wastage of manufacturing Fly Ash Brick onsite is reduced to around 2-5%.

Applicability

Due to their light-weight nature they are best suited for multi-story buildings.

Appearance

Cement grey in colour they have uniform structure. They usually weigh around 2.6 kg.

Weight

Lighter, in weight thus resulting in a decrease in stress and strain.

Strength

Fly Ash Bricks features High Compressive Strength, Endurance, and Durability.

Water Absorption

Water Absorption of Fly Ash bricks very less, unlike clay bricks for which bricks should be soaked in water for 24 hours.

Sustainability

For various factors, Fly Ash Bricks is considered to be sustainable. Top soil depletion is avoided, water consumption is minimized, work force is reduced, raw materials are optimized and pollution is controlled.